Prototype de PCB en toute simplicité

Service complet de prototypage de PCB personnalisé.

Centre d'aide

Service hotline

+86 571 8503 9969

9:00 - 18:00, Mon.- Fri. (GMT+8)

9:00 - 12:00, Sat. (GMT+8)

(Sauf les jours fériés chinois)

FR / USD

Bienvenue sur PCBWay

- Nouveau client?

- Créez un compte

Accueil

Devis immédiat

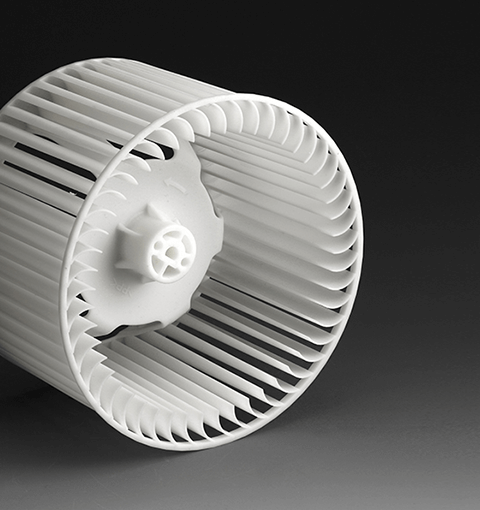

CNC | Impression 3D

Assemblage(PCBA)

Conception de circuits imprimés

OEM

Produit & capacités

Présentation

Avis

Projets partagés

Boutique

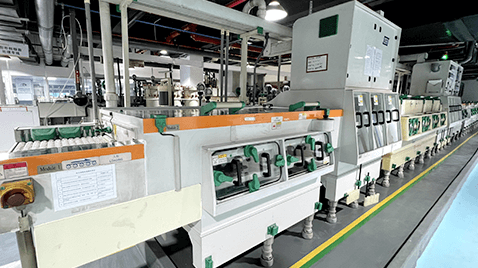

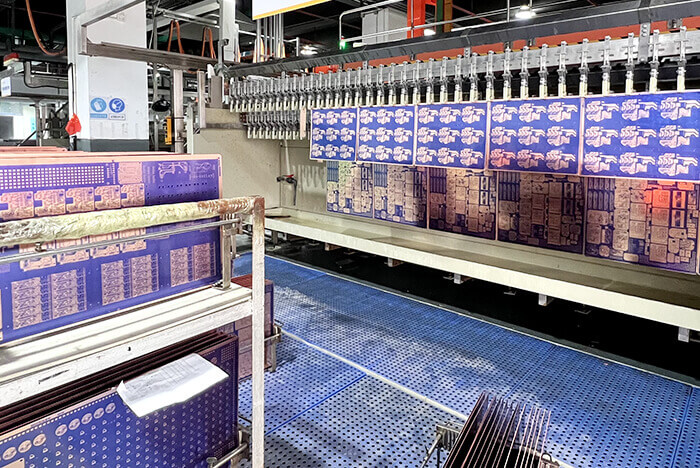

Printed Circuit Boards

- PCB Capabilities

- Advanced PCB

- Advanced PCB Capabilities

- PCB Prototype

- Flex and Rigid-Flex PCBs

- Flexible PCBs

- Rigid-Flex PCBs

- Aluminum PCB

- Metal core PCBs

- High Frequency PCBs

- High-TG PCBs

- Thick-Copper PCBs

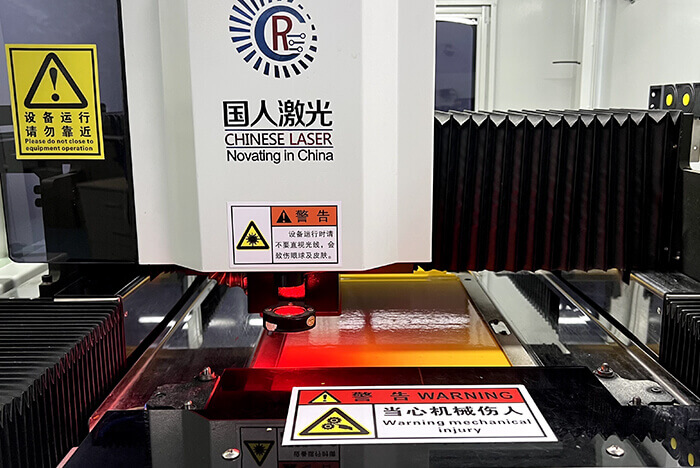

- HDI PCB

- LED PCB

- Quick turn PCB Fabrication

- PCB Prototyping

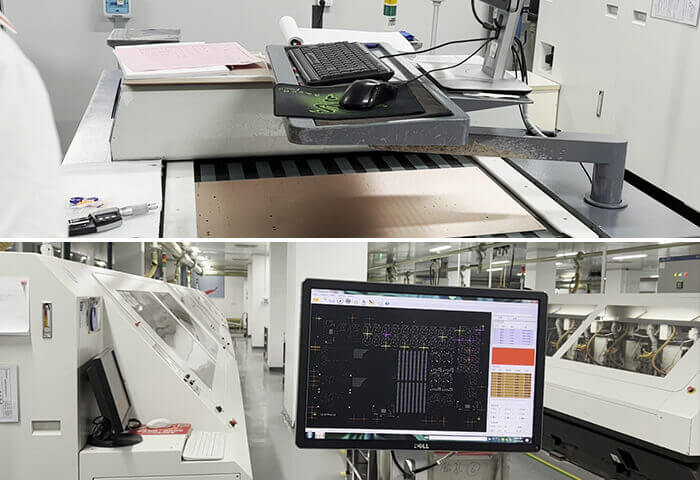

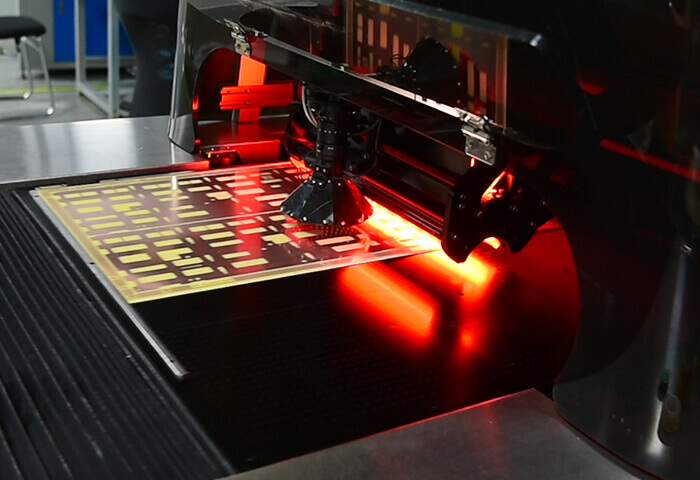

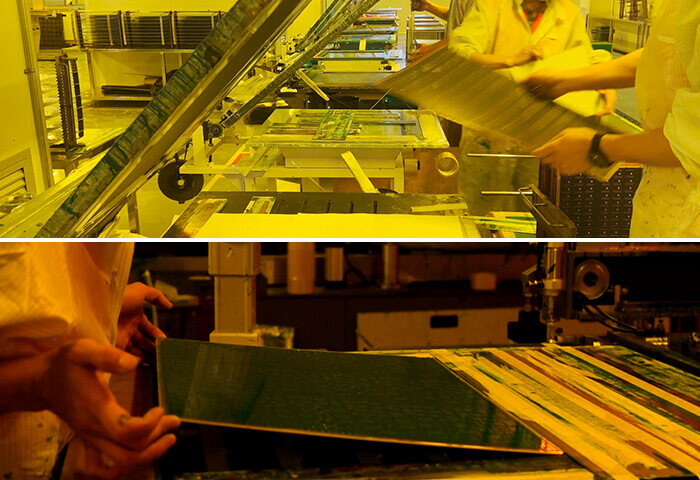

- PCB Production Process

- PCB Products

- PCB Engineering Questions

- FAQ of PCB

SMD-Stencils

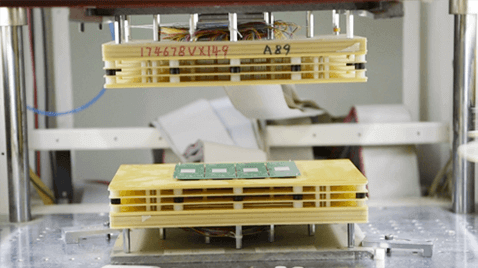

PCB Assembly

- PCB Assembly Overview

- PCB Assembly Capability

- SMT Ordering Necessary Files & Info

- SMT Assembly Capabilities

- Mixed Assembly Advantages

- Through-Hole Assembly

- BGA Assembly Capabilities

- Components Sourcing

- Panel Requirements for Assembly

- Special Reminders

- File Requirements

- Production Process

- PCB Assembly Products

- PCB Assembly FAQ

PCB Design-Aid & Layout

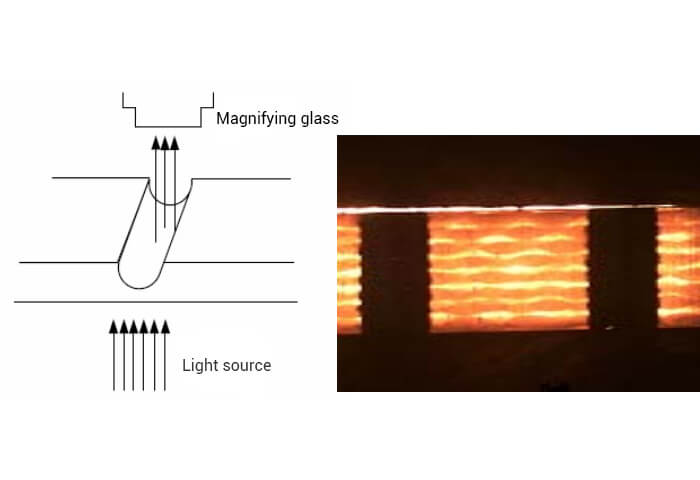

Drills & Throughplating

Layer buildup

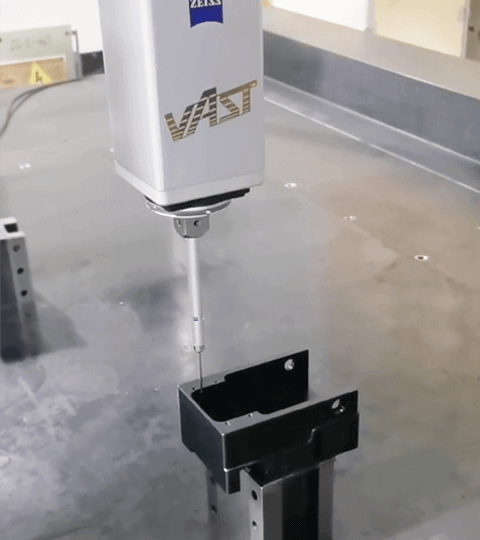

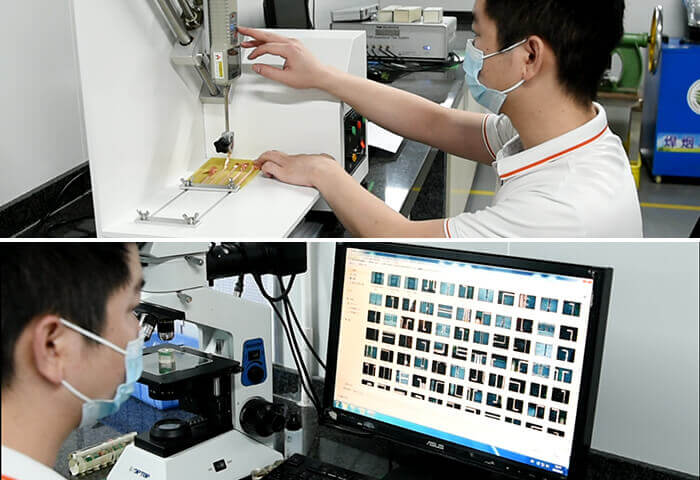

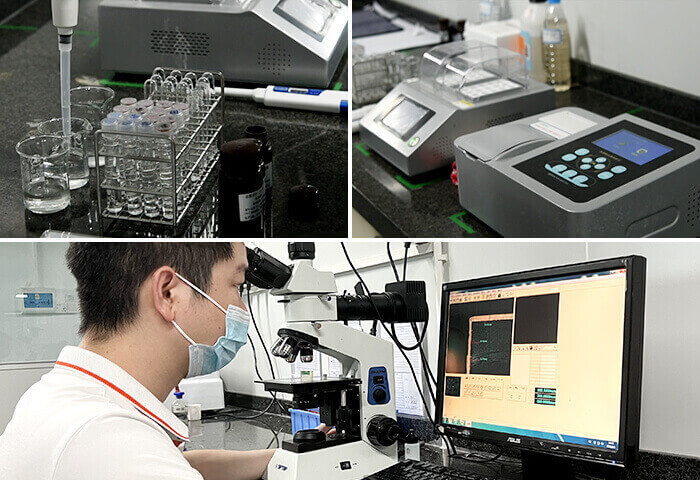

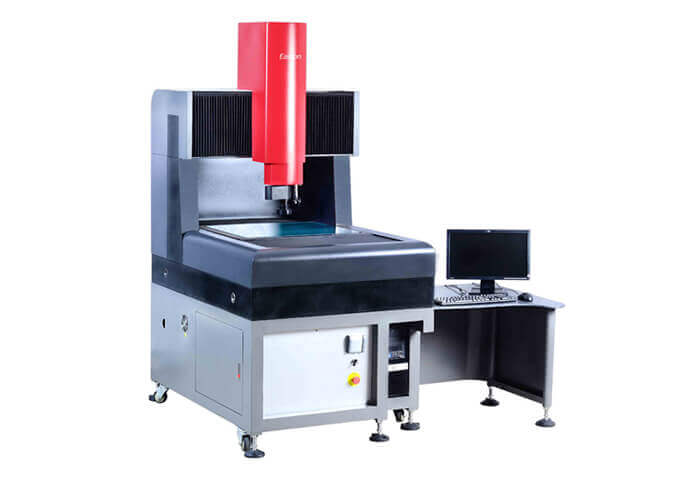

Quality

CNC Machining

Sheet Metal Fabrication

Additional Services